Laser marking machines

Laser marking systems – precision laser marking machines for industrial applications

Types of laser marking systems

Fiber laser marking systems excel in delivering swift and accurate engraving on metals and plastics, whether using a Q-switched or MOPA technologies, making them ideal for industrial applications. On the other hand, the benefit of MOPA technology is best seen when a mark is required that does non cause any deformation or ablation to the surface of the material, this is possible due to the ability of the laser to produce much shorter pulses. CO2 laser machines with their longer wavelength, produced using a gas-filled tube, are ideally suited for working with organic and non-metallic materials such as wood, glass, and leather. These lasers are the perfect choice when looking to mark, cut, perforate or convert, available in a number of tuned wavelengths, enabling faster cutting of materials such as Polypropylene and PET based products up to 4 times faster. DPSS lasers are perfect for achieving high-contrast fine details. This technology, uses a YAG or YV04 crystal pumped by diodes to produce a superior beam, particularly useful in micro-marking tasks within the medical and electronics industries. This technology can also be utilised to produce light in the Green and Blue (UV) wavelengths, Green lasers are ideally suited for marking heat-sensitive materials, which would include both plastics and metals. Green is a better choice for transparent or coloured plastics orange and red are typically difficult to mark with other wavelengths. Aluminium and Copper, with their higher reflectivity, can be marked more effectively due to the higher brightness of the green laser making the reflectivity making it easier to combat the high reflectance of these materials. UV lasers create minimal heat damage to the surface of the material; they can create high contrast permanent marks on metals, glass and plastics, even when they are clear, perfect for difficult to mark medical and aerospace components.Key features of our laser marking systems

All our laser marking systems feature a motorized Z-axis that can be programmed via our software to automatically adjust to the product height to ensure focus is maintained throughout the process. Our plug-and-play rotary enables you to mark around cylindrical products whilst the addition of our CVS (Coaxial Vision System) and pattern matching software means accurate tooling and fixturing is no longer a prerequisite. These systems are perfect for high-speed marking and 3D engraving,. The non-contact nature of the process ensures no material wear while maintaining exceptional accuracy. Classified as Class 1, all our workstations adhere to rigorous safety standards. Additionally, our user-friendly software simplifies operation and enhances productivity.Compatible materials for laser marking & surface processing

Laser marking systems are incredibly versatile, capable of working with a wide range of materials to produce precise and permanent marks. They are particularly effective on metals like:- Steel and stainless steels

- Aluminium, titanium and alloys

- Nickel alloys

- Gold Silver and other precious metals

- Tool SteelsCopper and Copper alloys

- ABS and other styrenes

- Polypropylene

- Acrylic

- HDPE

- Nylon

- Polycarbonate

- Cleaning away contaminants,

- Stripping coatings for repairs,

- Improving adhesion.

Applications: reliable traceability & direct part marking (DPM)

Laser marking systems are crucial in industrial environments for creating long-lasting marks necessary for effective tracking. With direct part marking (DPM), manufacturers can mark serial numbers, barcodes, and data matrix codes directly onto components. enabling product identification and traceability. These durable marks resist wear, chemical exposure, and harsh conditions, maintaining their readability over time.Industries using our laser marking solutions

Industries such as automotive and aerospace favour laser marking due to its precision and durability, which ensures long-lasting traceability. Within medical technology, marking plays a vital role by marking difficult to mark materials, complying with regulations and safeguarding patient safety. Electronics manufacturers typically want to mark components or PCB’s for future identification. At the same time, companies producing consumer goods employ laser technology to personalize products with logos and QR codes to strengthen their brand image.Benefits of choosing our laser marking systems

Our laser marking systems provide rapid and accurate results, ensuring marks that are both clear and long-lasting. In contrast to traditional methods, they reduce overall ownership costs by minimizing maintenance needs and consumable expenses. Additionally, these non-contact systems are environmentally friendly as they function without the use of inks or solvents, resulting in a cleaner process. . Additionally, these systems are eco-friendly since they operate without chemicals, significantly reducing waste and emissions.Standalone vs. integrated laser marking systems

Standalone workstations are single-cell systems and are not integrated into a production line, making them ideal for tasks involving low to medium-volume marking. They offer flexibility, the ability to do quick program changes and with minimal setup and downtime, which suits prototyping and specialized production runs perfectly. Fully integrated solutions combine effortlessly with automated production lines, providing high-speed and continuous operation. These systems boast advanced integration features that facilitate direct communication with manufacturing execution systems (MES) or ERP platforms, using common communication protocols that allow for real-time data tracking and process automation.Selecting the right laser marking system for your needs

Choosing the ideal laser marking system requires assessing your unique needs, budget, and the materials you wish to mark. Customizable systems offer flexibility to help meet your exact specifications, while modular designs enhance versatility. Striking a balance between cost and performance is crucial for achieving the perfect solution, where software integration and personalised solutions contribute to seamless operations and an efficient workflow.Popular laser marking system

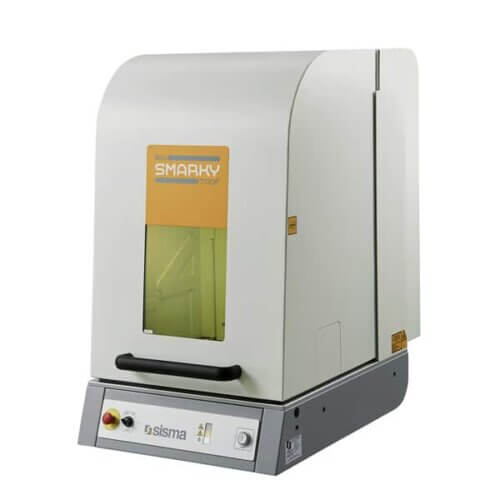

We offer a large range of laser marking systems from Sisma. These Sisma laser marking systems deliver high-end marking capabilities across numerous industrial applications and are renowned for their durability and efficiency.LWS-A, Laser marking stations with three axes

LWS-A is a laser marking station from Sisma that is flexible, sturdy and modular. Available at Laser Lines. More

LWS-M, 3-axis laser marking station with removable and height adjustable working plane.

LWS-M is 3-axis laser marking station that is flexible, modular, sturdy and intuitive system from Sisma at Laser Lines. More

BSP, 3-axis laser marking and engraving system with base

BSP 3 axis laser marking and engraving system is compact and sturdy, featuring a spacious working chamber. More

BSP PICO is a laser marking and engraving machine which uses a picosecond laser source

BSP PICO laser marking and engraving machine from Sisma is compact and advanced system with picosecond laser. More

WH-64-P, laser marking station with 64-pallet automatic storage

Productive and flexible. autonomous laser marking station from the Sisma that is available at Laser Lines with 64-pallet automatic storage More

Modo, universal systems for laser processes

The MODO system offers an unprecedented range of configuration and is customizable according to specific needs. More

BSP+WH-6P CBOT, laser station consisting of BSP laser marker with 6-pallet warehouse and collaborative robot

BSP laser marking station with 6-pallet warehouse and collaborative robot: an automated storage system from Sisma. More

BIG SMARKY, laser marking and engraving system

Big Smarky is laser marking and engraving system by Sisma, that is practical and versatile, that is offered by Laser Lines. More

BIG SMARK. laser marking and engraving system with base

Big Smark is a laser marking and engraving system that is versatile, digitaly advanced system from Sisma, available at Laser Lines. More

SART, laser marking and engraving system with rotating table, on base

SART is laser and engraving system by Sisma that is highly productive, functional and flexible system available at Laser Lines. More