Laserline has optimized its portfolio in the high-power blue diode laser segment. In doing so, the company is making important advances in focusing properties. This is because with output powers of up to 800 watts blue lasers will be available with 20 mm-mrad beam quality, while lasers with output powers of up to 1,500 watts will be available with 30 mm-mrad beam quality. These improvements simplify the joining of thin copper contacts as well as welding with scanner optics.

Laserline has optimized its portfolio in the high-power blue diode laser segment. In doing so, the company is making important advances in focusing properties. This is because with output powers of up to 800 watts blue lasers will be available with 20 mm-mrad beam quality, while lasers with output powers of up to 1,500 watts will be available with 30 mm-mrad beam quality. These improvements simplify the joining of thin copper contacts as well as welding with scanner optics.

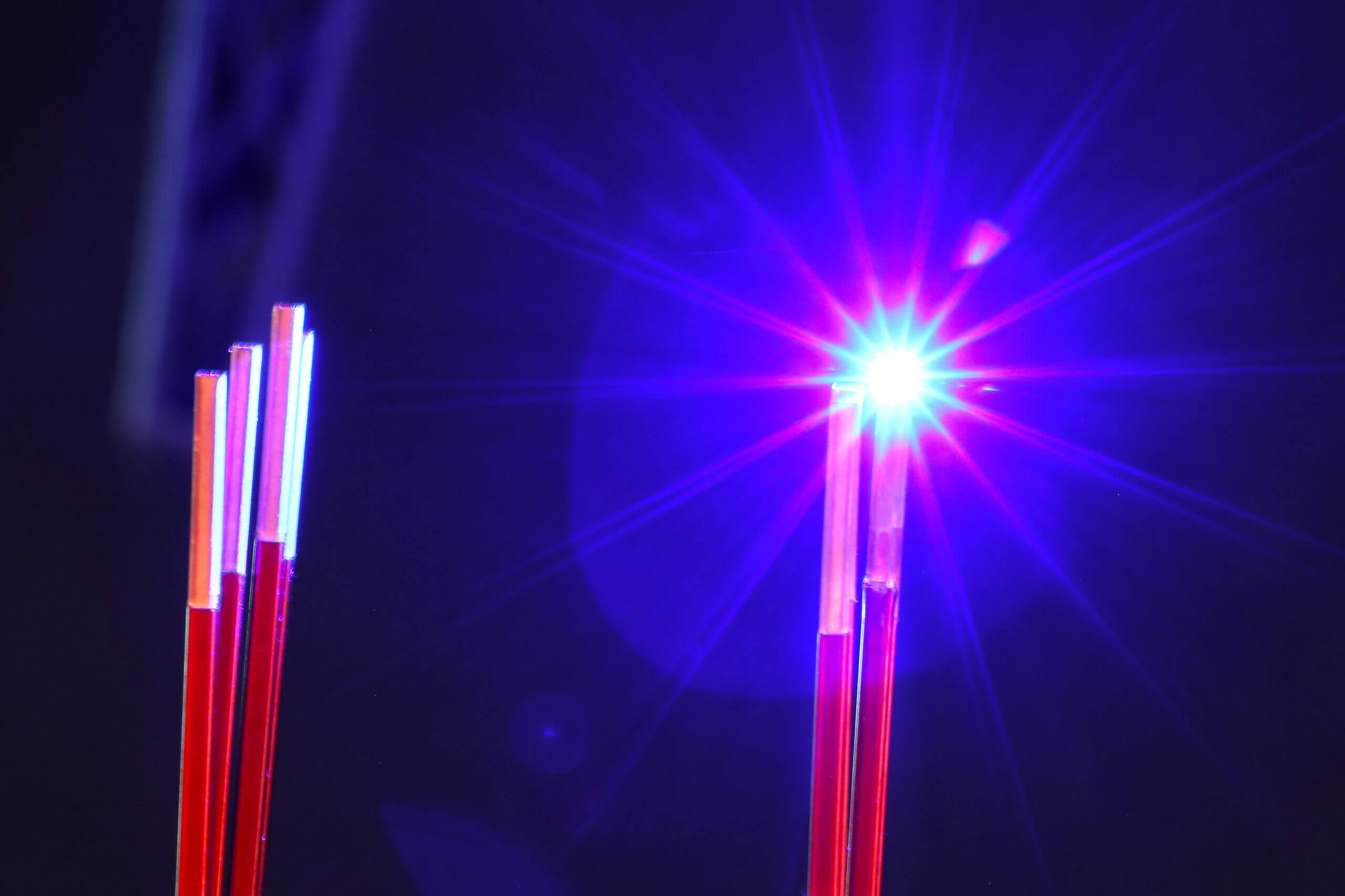

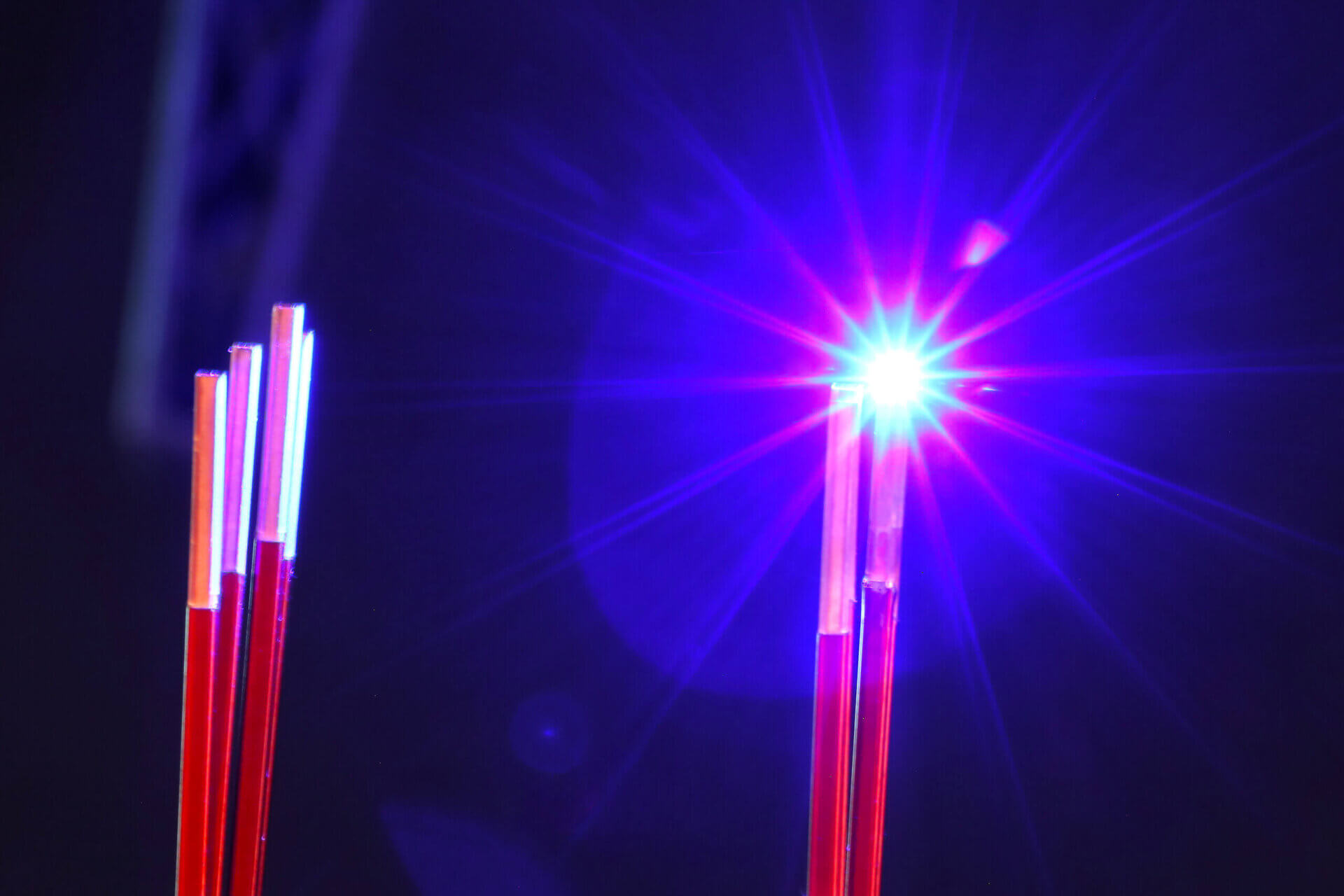

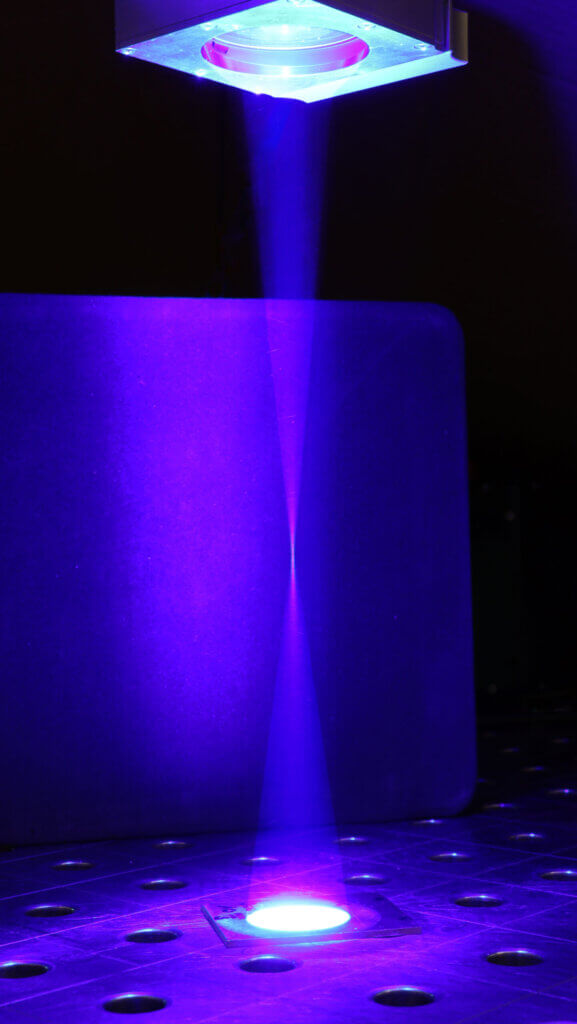

Laserline, the leading international developer and manufacturer of diode lasers for industrial material processing, is optimizing its portfolio in the LDMblue high-power diode laser segment with 450 nm wavelength. Primarily developed for copper material processing in the electronics industry, these blue diode lasers are now available in six power levels between 300 and 2,000 watts. In addition, important advances have been made in terms of focusing properties. With the LDMblue 300-20 and LDMblue 800-20, a beam quality of 20 mm-mrad is now available at output powers of up to 800 watts. For the 1,500-watt systems, the beam parameter product has been reduced from the previous 60 to 30 mm-mrad. As a result, the LDMblue 1500-30 offers an improved beam quality by a factor of two at identical power. Besides, blue diode lasers with output powers of 500, 1,800 and 2,000 watts with a beam parameter product of 60 mm-mrad are now available for applications with medium-to-high power requirements (LDMblue 500-60, 1800-60 and 2000-60).

Improved beam quality.

Improved beam quality.

The advances in beam quality are especially significant for joining applications related to electrical conductor technology. Due to the smaller focus diameter, extremely thin and highly filigreed copper contacts can be precisely machined. As a result, very narrow joining seams are realized. The improved beam quality enables greater working distances and simplifies scanner welding applications. Further advantages may be obtained by combining with the finely graduated power regulation of the Laserline laser systems. Critical energy input into seam-adjacent component zones is avoided, while exceptionally calm melt pools are created. This allows workpiece surfaces to be melted without major spatter formation. The cooled seams are smooth and virtually pore-free, which further impresses with high stability and excellent electrical conductivity.

In electronics manufacturing, blue diode lasers are now considered a key technology. They have opened up a wide range of new options for processing conductor materials in the non-ferrous metal sector. Light in the blue wavelength spectrum is absorbed by non-ferrous metals up to 20 times the capacity of infrared light. A lot less energy is therefore required to melt component surfaces compared to conventional infrared lasers. For the very first time, these blue diode lasers have made a controlled heat conduction welding process possible. Highly conductive non-ferrous metals such as copper and gold can now be joined with ease. Even the thinnest copper components can now be welded without artificial material reinforcement. LDMblue diode lasers have also been successfully used in non-ferrous metal-based coating processes and currently, they are also being tested in maritime applications and high-power lighting technology. In the long term, output powers of up to 5 kW may be considered realistic.

Improved beam quality.

Improved beam quality.